Thermobonding is a process where fibres in the webs can be bonded together by applying thermal heat. In this way non-wovens can be shaped for industrial purposes like the aviation and the automotive industry. There are different thermobonding systems available to devorm non-woven materials like a drum oven, through-air bonding machine and a thermobonding belt oven. The thermobonding oven operated by a belt is discussed below, this type of machine is predominately applied for heavy web qualities.

Thermobonding is a specific process where a web of non-thermoplastic fibres and thermoplastic fibres will be pressed and heated to melt together gradually followed by a cooling process where the fibres solidify within the desired compressed area and shape. The thermoplastic fibres are necessary to make the thermobonding process possible, this part of the fibres become viscous during the thermal treatment and enables the polymers to flow to get fibre-to-fibre crossover points. This process eventually leads to the formation of bonding regions. The actual end products like the non-wovens for the automotive and aviation industry are predominantly applied in the interior of vehicles, but also other non-woven products like filters, geotextiles, hygienic materials for diapers and so on are manufactured by means of a thermobonding oven.

Nowadays, most thermo-bonding ovens are efficient when it comes to energy consumption, most of these type of ovens have proper insulation which reduces the heat loss to a minimum. Thermobonding belt ovens are ideal for processing large quantities of non-woven products in a continuous manufacturing process. These type of ovens offer high accuracy when it comes to the temperature regulation and heat air flow distribution over the entire width of the product, this is to get uniform bonding results.

Advantages of a thermobonding oven:

- Suitable for processing voluminous quantities

- Good for heavy web qualities

- Relatively easy to maintain

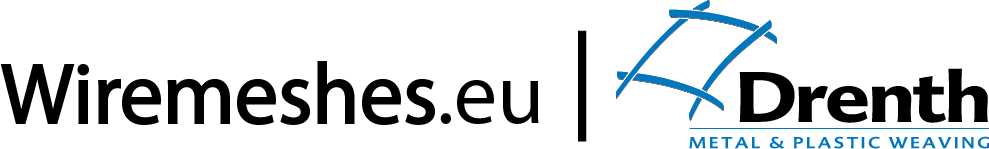

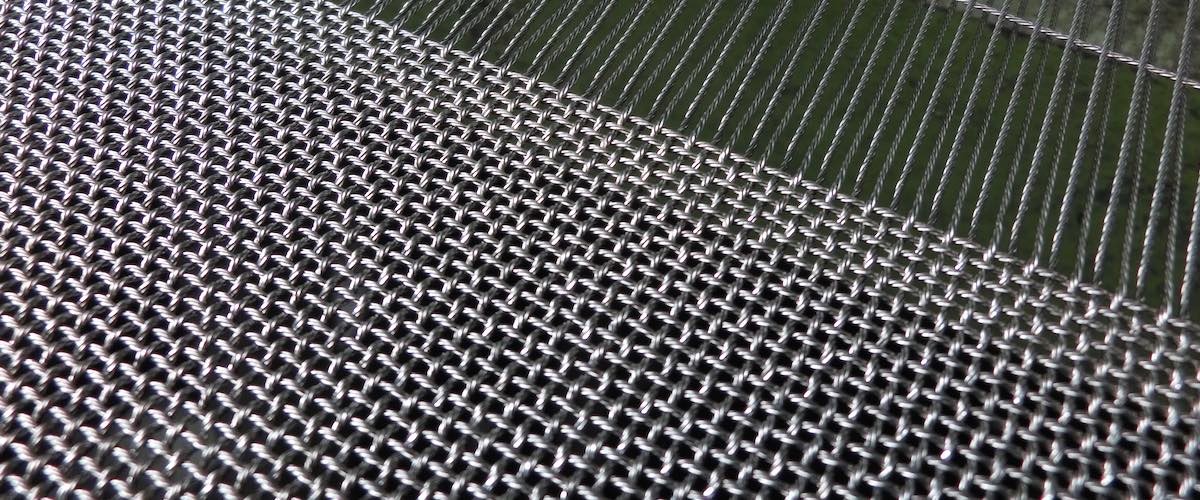

Wiremeshes.eu | Drenth Holland bv is able to manufacture various types of thermobonding oven belts to customer specification. Most woven wire mesh belts for thermobonding ovens contains stainless steel with a cable in the warp direction for the flexibility and a pin wire into the weft direction for the stability. The mesh opening can be adjusted according to customer needs depending on the type of the to be produced non-woven.