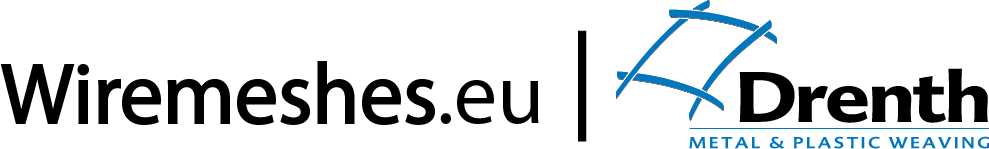

Phosphor bronze wire mesh is used within various niche markets such as the security paper industry (for dandy roll clothing to emboss watermarks), for cloth filters and belts, for electromagnetic interference shielding, for electrical parts of products, wind tunnels (to test airplane aerodynamics) and for house architecture.

Phosphor bronze wire mesh properties

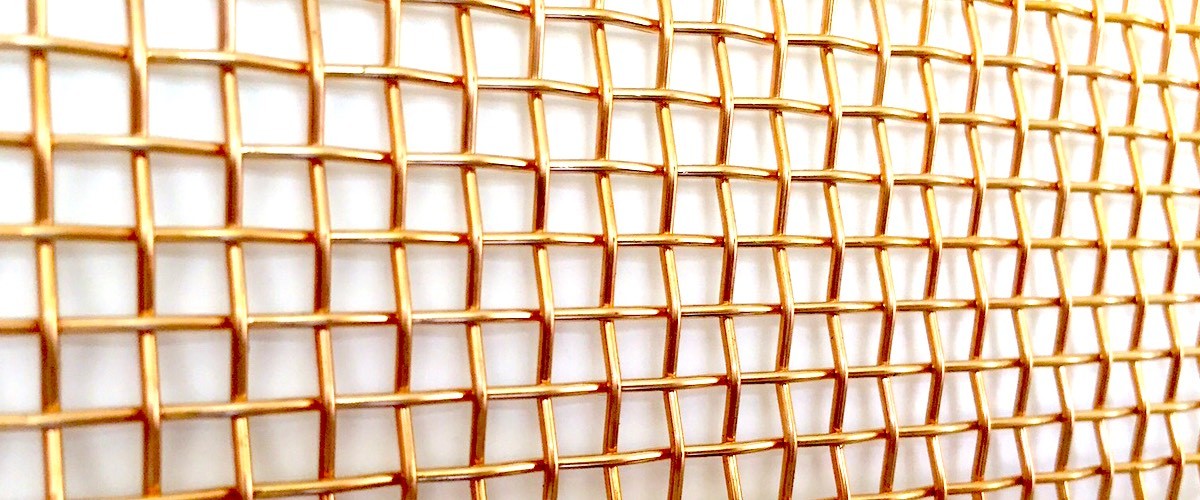

Some factories make use of bronze belts or other phosphor bronze wire mesh due to the beneficial properties like its electrical conductivity and low thermal conductivity during the manufacturing process. This material can also be produced up to 6 meters wide, which is a huge benefit for the paper industry in general.

Phosphor bronze wire mesh is really strong, tough with a low friction coefficient, solderable, easy to shape and it can be produced with a fine structure. It is mostly applied in severe circumstances where chemical corrosion, wear and metal fatigue play a part.

Common technical options and specifications

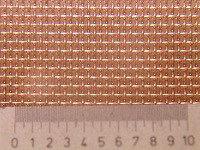

- Wire diameter: 0.17 mm – 1.00 mm

- Mesh opening: 0,19 mm – 4,00 mm

- Wires per cm: 2×2/cm – 28×28/cm

- Mesh: 5 – 71

- Colour: bronze

- Annealed and unannealed

- Plain weave