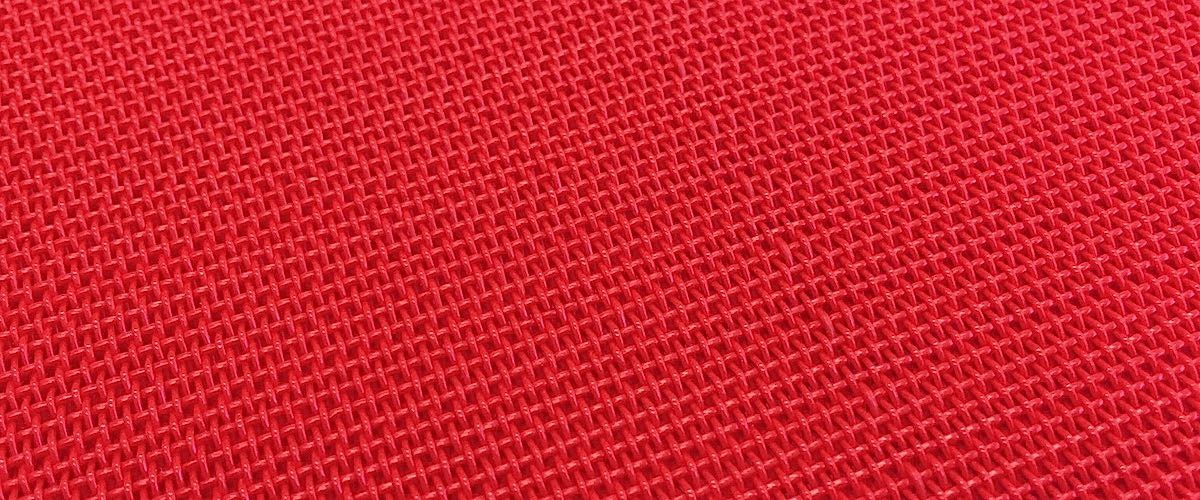

Monofilament polypropylene mesh is a slightly different product beside polyester mesh as it enjoys other highly valuable properties. This type of woven fabric has been designed for the cheese and dairy industry but it is also an excellent material for the chemical industry, since polypropylene is very resistant to aggressive chemicals.

Monofilament polypropylene mesh is a slightly different product beside polyester mesh as it enjoys other highly valuable properties. This type of woven fabric has been designed for the cheese and dairy industry but it is also an excellent material for the chemical industry, since polypropylene is very resistant to aggressive chemicals.

Monofilament polypropylene mesh industries

Most of the monofilament polypropylene mesh is finished with high frequency (melted) edges and a metal clipper or woven seam to make an endless belt. This type of belt is mostly used within the soft and wet cheeses industry, such as cheddar and mozzarella cheese, for drainage purposes. Many clients prefer the colour red as it is easily detectable in the end product is case of damage.

Common technical options and specifications

- Wire diameter: 0.50 mm – 0.60 mm

- Weave thickness: 1.9 mm (double layer)

- Wires per cm: approximately 20x2x5.5/cm

- Mesh: approximately 51x2x14

- Maximum temperature: approximately 100 °C | 230 °F

- Depends on application

- Colour: red/transparent

- Hydrolysis resistance

- Aggressive chemicals resistance

- Food grade