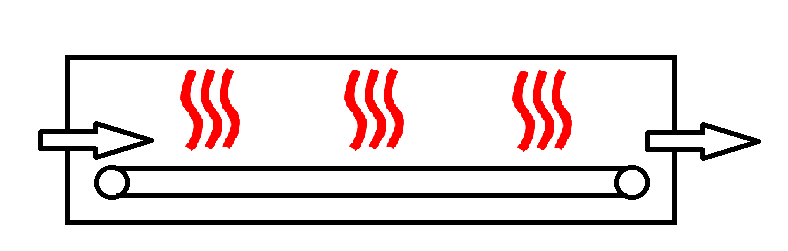

The belt dryer and the vacuum band dryer is an installation which is used for drying purposes for foods and non-foods. Most of the time the belt dryer dries continuously with a hot or cool air flow.

Belt dryers are mainly designed to provide products with a gentle thermal treatment. Products which are mostly wet are diffused equally on a wire mesh belt into the infeed chamber of the belt dryer. Most of the belt dryers have a wire mesh belt in a horizontal position which conveys the product through the drying sections. Gas or air flows circulate through the drying sections over the wet products. Each section within the dryer can be equipped with a heat exchanger or either a ventilating fan which enables the process operators to control each section separately. In other words each section within this type of belt dryer can be controlled and adjusted when it comes air flows and temperatures. Furthermore, the running speed of the wire mesh belt within the belt dryer can also be adjusted which gives an additional option to influence the drying time. There are also possibilities to cool or heat the different sections indirectly or directly by means of oil, steam, hot water, hot gas etc. which obviously depends on the type of belt dryer.

Various belt dryer features

In general belt dryers and coolers are designed in a modular setup. Each type of belt dryer contains at least one entry point which can be called an infeed head, the conveyor belt to transport the product onto a porous wire mesh belt for air permeability, and the discharge end for output. In general each setup works with an air flow through or over the product to dry the product. Various setups are possible:

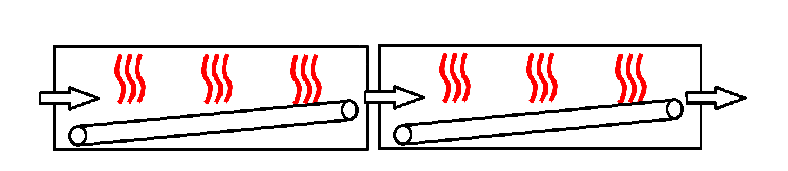

Single-Belt dryer

A Single-belt dryer is often used for drying products which are dusty and cannot be moved. The air flow can be reversed through the product and wire mesh belt during the drying process.

Multi-stage belt dryer

Multi-stage belt dryers are deployed for products which are insensitive to intense movements like wet agglomerate, since products need to go from belt to belt and can disintegrate during the transfer. The temperature can be adjusted very quickly based on the type of required drying process of the particular product.

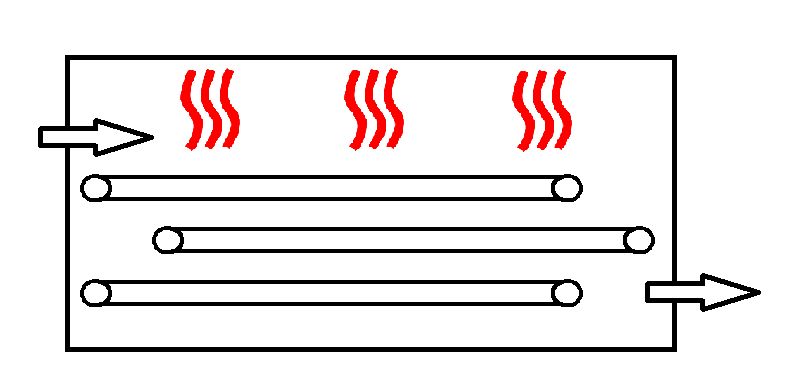

Multi-belt dryer

The Multi-belt dryer is designed for processing larger quantities which require a long period within the belt dryer to dry the product. There are two options to heat the dryer, internally or by means of an air handling unit which is external.

Vacuum band dryers

Vacuum band dryers are installations which handle a continuous flow of paste and viscous liquid, in other words materials which are heat sensitive and not totally solid. The vacuum band dryer is a big round chamber (like a horizontal silo) which is vacuum from the inside (an important difference compared to a belt dryer), it contains a number of synthetic wire mesh belts which pass over steam or hot water heated elements. These machines are provided with different capacities ranging from a single vacuum band dryer up to a ten belt vacuum band dryer, obviously the vacuum chamber as well as the conveyor belt are in food grade. Some typical applications for this type of machine are; extracts, enzymes, food paste and pharmaceutical products, mostly products which contain a certain amount of sugar. The best use of a vacuum band dryer is at low temperatures under vacuum circumstances for continuous drying. The product is spread equally on the belt at the feeder point of the machine in order to dry as the belts moves through the vacuum band dryer.

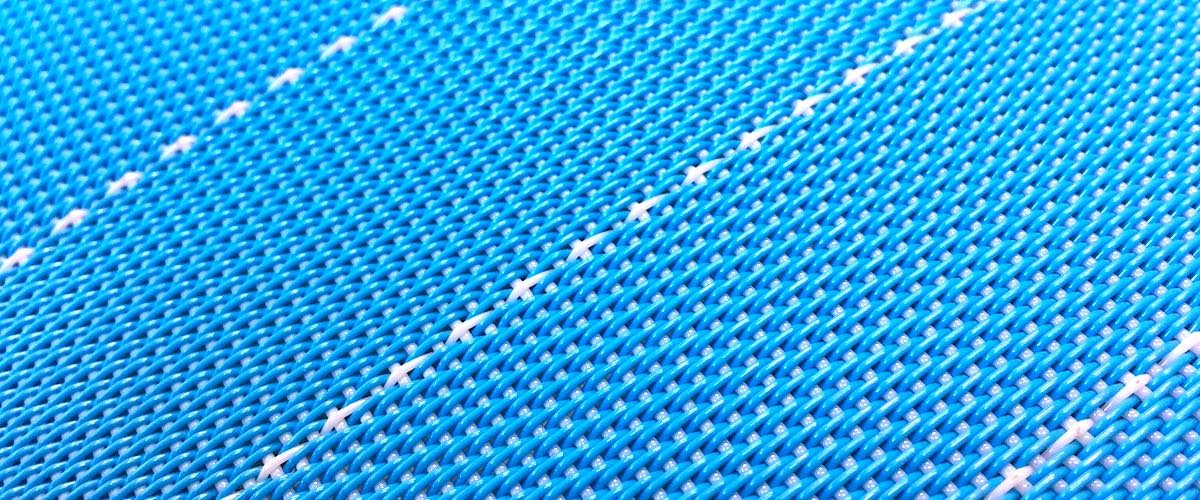

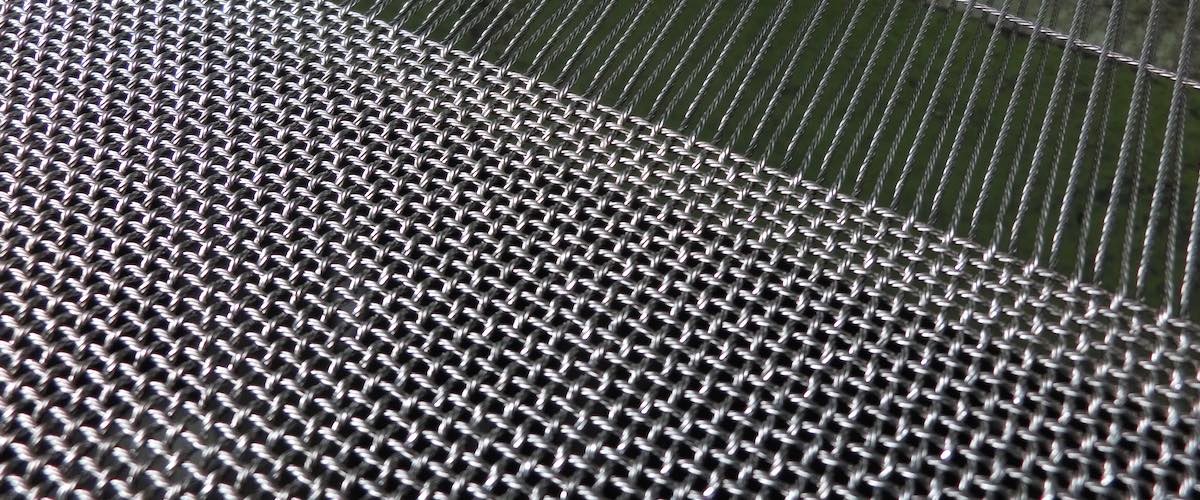

Types of drying belts

There are various types of drying belts available for belt dryer installations, since the nature of the products to be dried require various approaches which can vary as much as the belts inside those machines.

Many belt dryer installations are equipped with chain-guided conveyors which can roughly be divided into three types: wire mesh belts, hinge conveyor belts and steel plate conveyors. A highly durable alternative are belt dryers equipped with a chainless woven wire mesh belt, those machines do not work with chain-guides but by means of active steering of the rolls. The very equal distribution of air and liquid permeability is a major benefit of woven wire mesh belts compared to hinge conveyor belts and steel plate conveyors. Drenth Holland is a specialist when it comes to woven wire mesh belts for non-chain-guided belt dryers.

Industries

Belt dryers have applications in particular within the following industries: chemical, ceramics, pharmaceutical, foods, non-wovens, minerals, plastics and wood. Some examples of common products to dry are: molding materials, fruits, vegetables, couscous, wood fiber boards and so on.