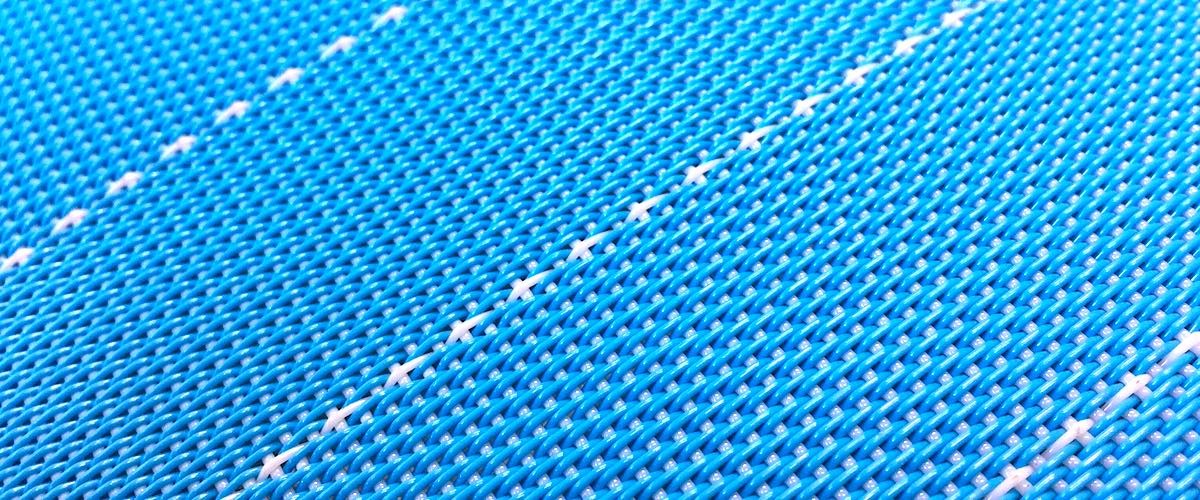

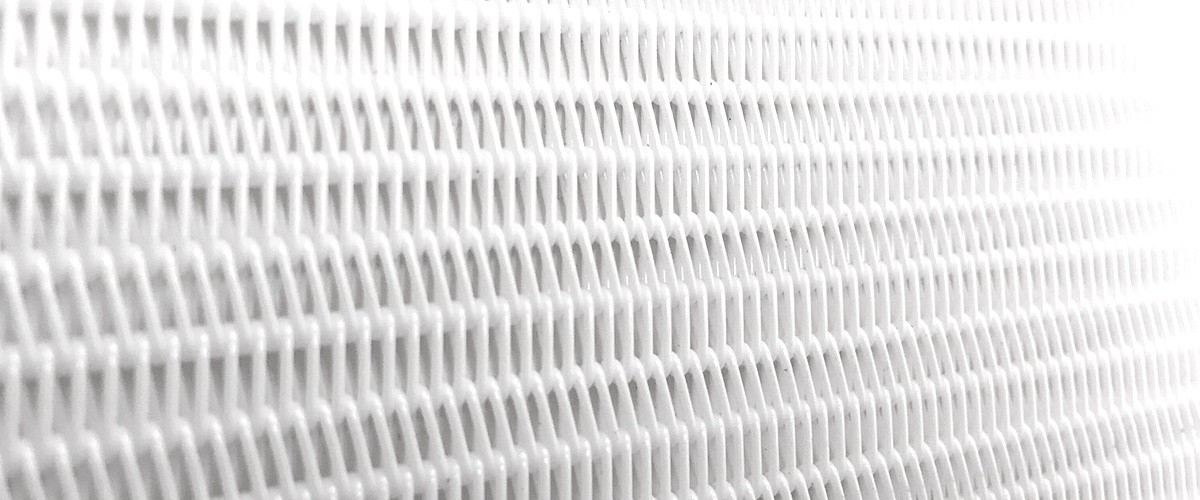

A belt filter press is an industrial dewatering machine which separate liquids from bio solids/sludge. Another type of belt filter is the vacuum belt filter, this is usually a very large and wide installation for processing high volumes. These type of belt filters are used within the water treatment industry, sewage treatment industry, food industry, mining industry, mineral industry, paper industry, pharmaceutical- and chemical industry. Those polyester wire mesh belts are built to withstand severe conditions like humidity and tension.

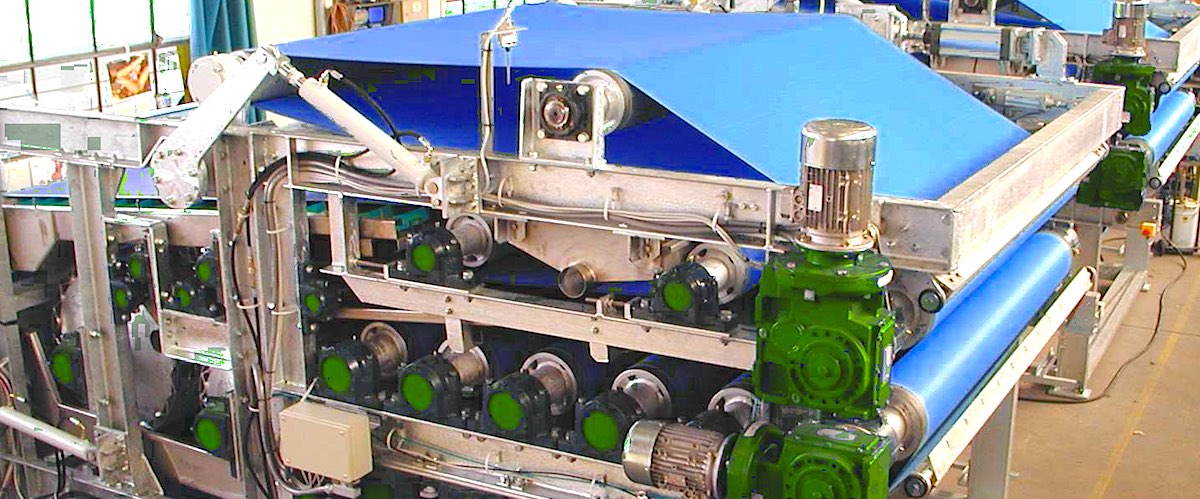

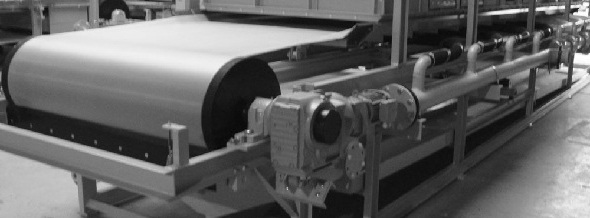

Belt filter press in operation

Belt filter presses produce mechanical pressure on the slurry by sandwiching the sludge between two monofilament wire mesh belts which squeeze the water out of the sludge. The woven wire mesh belts within these belt filter presses are on high tension and follow a specific path along various rolls with a decreasing size of diameter. When the woven wire mesh belt passes the final pair rollers at the end of its path, the filter belts are separated where the filter cake (result of the pressed sludge) is scraped off, and ends up in a receiving container.

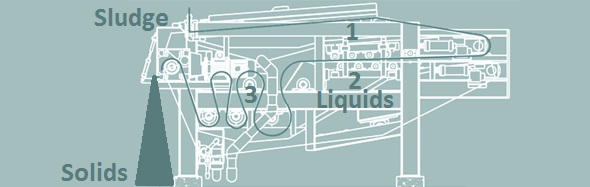

The belt filter press can basically be divided into three main areas:

- The gravity dewater area where sludge is draining freely from water by means of gravity on a porous filter cloth belt/woven wire mesh belt

- The wedge area where the remaining slurry is bought together by means of rollers and filter cloth

- The pressure area where medium to high pressure is applied on the sludge in order to drain the solids intensively

In other words, this filtration process is all about draining by pressing sludge between wire cloth belts in order to dewater the sludge for further processing.

Wire mesh maintenance improves performance

The woven wire mesh belt is also known as the filter cloth within the belt filter press. The filter cloth within this machine is one of the key parts of the belt filter press as it determines the actual output and thus the overall quality of the dewatering machine.

The effectiveness of the belt filter press can be increased by adjusting the pressure on the wire mesh belt, this filter cloth is able to handle these kind of pressure differences across the total belt. In other words, these belts need to be of top notch quality and need to be maintained regularly to ensure a continuous and effective draining process.

Adding a flocculent or filter aid during the draining process can also help to maintain the filter cloth as the open spaces in the wire mesh are more likely to stay open instead of becoming blocked. Thus it will also support the output of dry solids as the drainage flow keeps on working in a continuous way. The woven wire mesh belt can be cleaned during the operation by means of sprinklers which spray water under high pressure at the returning position of the belt, this is to avoid blockage of the wire mesh belt.

Vacuum belt filter

Vacuum belt filters also known as horizontal belt filters are usually a lot bigger compared to a belt filter press and these installations work based on the principles of gravity instead of pressing. Vacuum belt filters are different when it comes to the treatment of sludge and the output pertaining to belt filter press.

Vacuum belt filters can process high volumes of sludge which means reduced operating costs compared to other filtration alternatives. However this installation is not only used to separate solids from liquids, but foremost to obtain a output of cake with a high purity level. This installation washes the sludge at different stages on the wire mesh belt/filter cloth belt in order to obtain this pure cake. This cake has a low moisture level at the output of the vacuum belt filter and without the small polluting particles due to the washing. However, the purity and moisture level at the end of the vacuum belt filter is higher compared to the belt filter press. Another benefit is the low energy consumption level of the vacuum belt filter in terms of economies of scale but also in terms of absolute energy consumption.

So the belt filter press as well as the vacuum filter belt make use of the same synthetic wire mesh in order to filter sludge. Drenth Holland bv is very experienced in the production of filter cloth within these installations, feel free to contact us if you have a question concerning these type of filter belts.